01 Introduction of Industrial Oil Cooler

The refrigeration principle of the oil cooler: the low-temperature and low-pressure liquid refrigerant exchanges heat with the surrounding water in the evaporator. The evaporator absorbs the heat of the oil and evaporates into a low-temperature and low-pressure gaseous state. During the evaporation process, the temperature of the refrigerant remains unchanged, and the refrigerant in the low-temperature and low-pressure gaseous state enters the compressor, is compressed by the compressor, and is compressed into a high-temperature and high-pressure gaseous state. Then it enters the condenser and exchanges heat with the indoor medium in the condenser. Part of the heat in the high-temperature and high-pressure gaseous state is absorbed by the medium, and the temperature of the medium rises. Then it enters the expansion valve for throttling, throttling is a process of rapid cooling, and the refrigerant becomes a low-temperature and low-pressure liquid. After that, the refrigerant enters the evaporator for heat exchange and evaporation, so as to realize the whole process of the refrigeration system. This cycle is carried out continuously, so that the oil can be continuously refrigerated.

02 Features

1. It has two control methods: fixed temperature and room temperature coherent control, and users can choose arbitrarily according to actual needs.

2. It has a variety of protection functions and provides passive alarm terminals, and real-time alarms for fault signals, and can also be connected in series to industrial equipment to provide alarm functions.

3. It has the functions of real-time temperature monitoring, super high oil temperature warning, alarm, and low oil temperature alarm, which can maintain the viscosity characteristics of the oil and make the machine run stably.

4. The main engine adopts a famous brand compressor imported from Europe, America and Japan, which is reliable in operation, high in efficiency and low in noise.

5. Imported high-quality oil pump, high pressure, high stability, durable.

6. Imported digital controller with high precision and wide application range.

7. Avoid affecting the precision of the machinery during work due to changes in oil temperature.

8. Avoid oil deterioration due to high temperature, keep the oil viscosity unchanged, and make the machine work stably.

9. Oil temperature control is based on human body temperature (indoor temperature). Customers can set the oil temperature according to the body temperature to avoid thermal deformation caused by the mechanical structure.

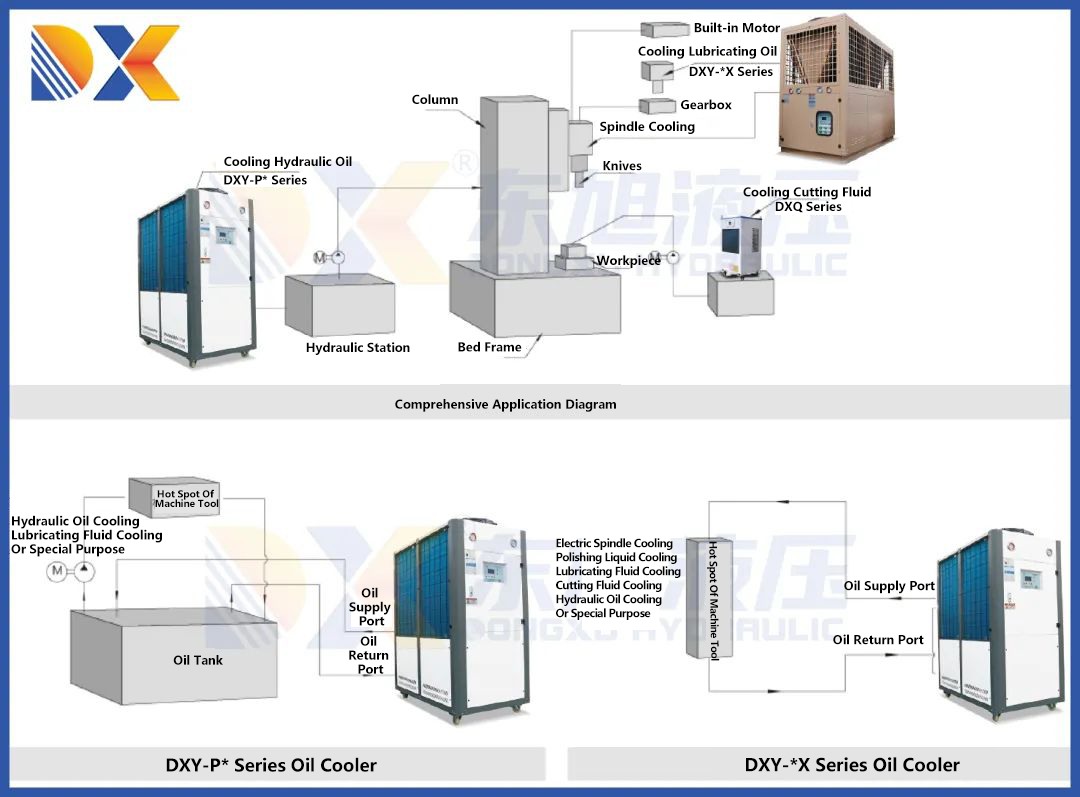

03 DONGXU Oil Cooler Application Cases

Cooling for Deep Hole Drilling

Cooling for Hydraulic Press

Cooling for Grinder

Cooling for Packing Machine

Cooling for Vertical Machining Center

Cooling for Refining Equipment

Cooling for Rolling machine

Cooling for Wind Power Station Hydraulic System

Cooling for CNC Cutting Machine

Foshan Nanhai Dongxu Hydraulic Machinery Co., Ltd.

MAIL: Jaemo@fsdxyy.com

WEB: www.dxhydraulics.com

WHATSAPP/SKYPE/TEL/WECHAT: +86 139-2992-3909

ADD: Factory Building 5, Area C3, Xingguangyuan Industry Base, Yanjiang South Road, Luocun Street, Nanhai District, Foshan City, Guangdong Province, China 528226

Post time: Feb-27-2023