Jiangsu HELIKE Fluid Technology Co., Ltd. is a wholly-owned subsidiary of Dongxu Hydraulics. It is specialized in the research and development, design, production and sales of aluminum plate-fin heat exchangers.

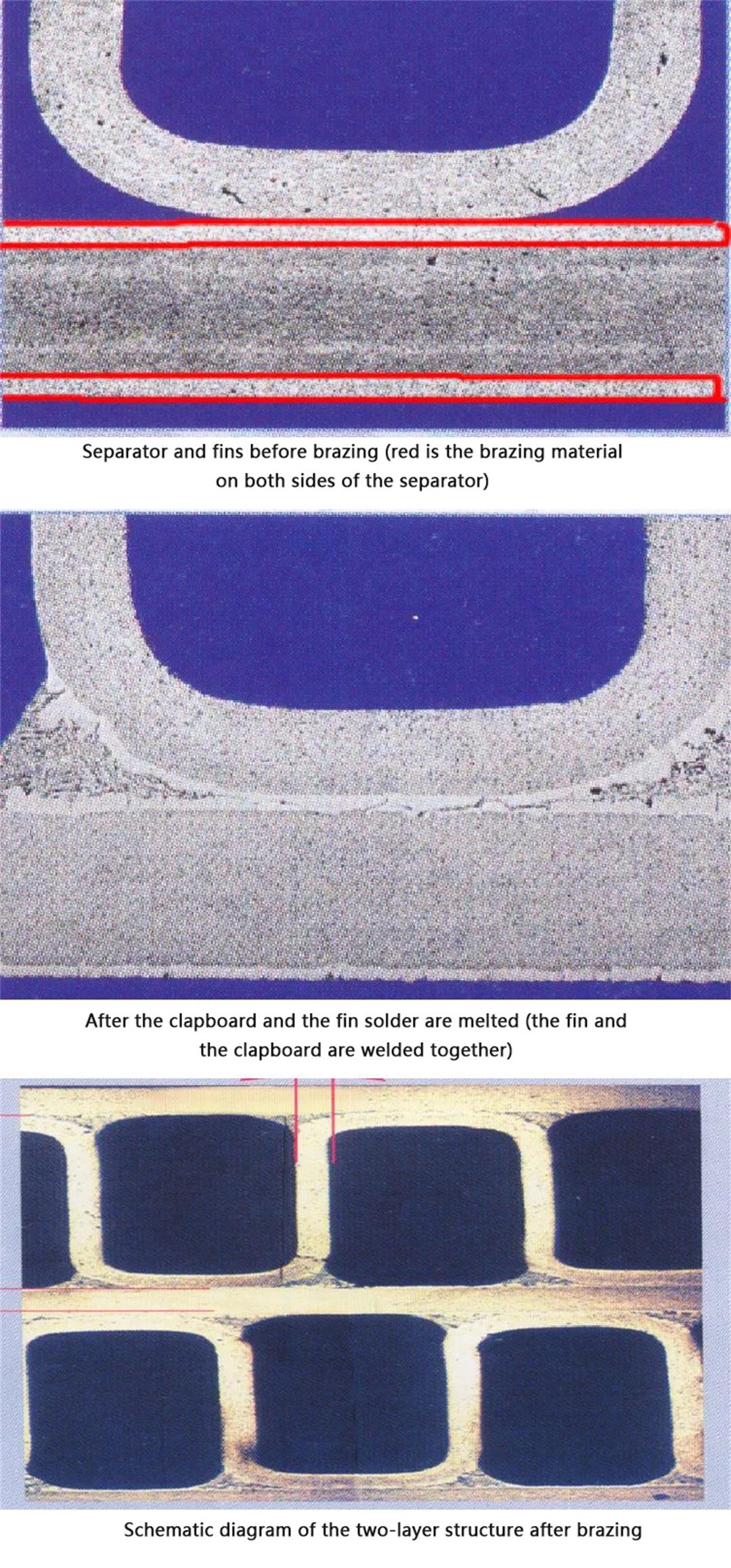

Mechanism of Vacuum Aluminum Brazing

Vacuum aluminum brazing technology uses aluminum alloy with a lower melting point than aluminum as the brazing material. This technique heats the weldment and solder above the melting point of the solder. But lower than the melting temperature of the base metal, the liquid solder fills the tiny gap between the two workpieces by infiltration and diffuses with the base metal, thereby realizing a method of connecting the workpieces to be welded.

Advantages of Vacuum Aluminum Brazing

①The heating temperature is low, so the physical and chemical properties of the base metal will not be affected or have little effect.

② Thousands of welds of complex parts can be welded at one time.

③The deformation of the parts is small, and it is easy to ensure the size of the assembly.

④Heating in a vacuum environment is beneficial to remove the grease and oxide film on the surface of the workpiece, and the surface brightness of the parts after welding is high.

⑤No flux required, no need to clean after welding.

⑥ Brazing and quenching (or some heat treatment) can be carried out at the same time.

Characteristics and Difficulties of Aluminum Alloy Brazing Process

Due to the unique physical and chemical properties of aluminum alloy, a series of difficulties and characteristics will arise during the brazing process:

The chemical properties of aluminum are relatively active, and its affinity with oxygen is very strong. In air at room temperature, the combination of aluminum and oxygen will form a dense AL2O3 film with a thickness of up to 0.1 μm. The oxide film is very dense, and its melting point is as high as 2050°C, far exceeding the melting temperature of aluminum alloy. At the same time, it will also hinder the good bonding between metals, and easily form slag inclusions and pores. Therefore, the pre-welding treatment of aluminum alloys and the prevention or reduction of oxide film formation in the heated state are very important. Therefore, it is very necessary to maintain a high vacuum in the furnace, reduce the formation of oxide film or remove the oxide film during the brazing process, especially in the process section of solder melting.

The melting temperature of the aluminum-based solder is only 50-80°C different from the melting point of the main aluminum alloy, and the operating space is small. Therefore, it is necessary to reasonably select the solder and determine the melting range of the solder, and at the same time, the solder and the base metal must have good wettability.

The correct selection of brazing temperature and holding time is very important to form a good brazed joint and improve the strength of the joint.

The dimensional accuracy of brazing components is high: for example, the dimensional tolerance of fin processing is controlled at ±0.03mm according to our experience, and the assembly quality/clearance must also be strictly controlled.

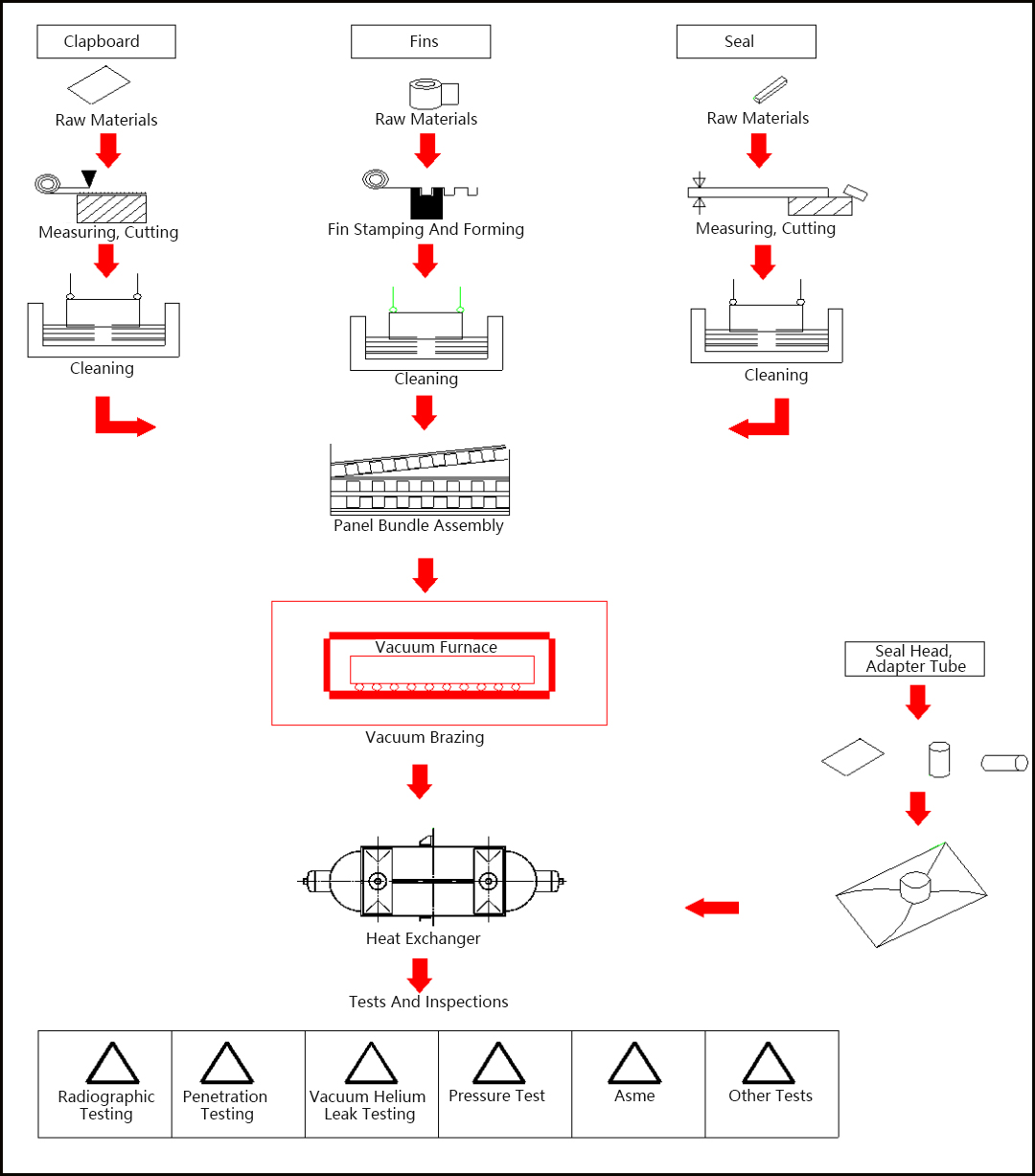

Process Flow of Aluminum Plate-fin Air Cooler

Our brands in China include:

①Foshan Nanhai Dongxu Hydraulic Machinery Co., Ltd.→DONGXU

Main products: air coolers, water coolers, oil coolers, bell jars, couplings, hydraulic systems, oil cylinders, cleaning windows, etc.

②Jiangsu Helike Fluid Technology Co., Ltd.→HELIKE

Main products: focus on high-quality special oil/air coolers for construction machinery.

③Guangdong Bokade Radiator Material Co., Ltd.→BOKADE

Main products: industrial machinery oil/air coolers, water coolers.

④Ningbo Fenghua Hydraulic Parts No. 3 Factory→DOXUDA

Main product: Accumulator.

⑤Guangdong Kaidun Fluid Transmission Co., Ltd.→KAYDUN

Main products: focus on hydraulic system, hydraulic component test bench, mobile equipment power station, lubrication system.

Finally, the relationship between the aforementioned company brands.

Foshan Nanhai Dongxu Hydraulic Machinery Co., Ltd. has three subsidiaries: Jiangsu Helike Fluid Technology Co., Ltd., Guangdong Kaidun Fluid Transmission Co., Ltd., and Guangdong Bokade Radiator Material Co., Ltd.

The holding company of Foshan Nanhai Dongxu Hydraulic Machinery Co., Ltd.: Ningbo Fenghua No. 3 Hydraulic Parts Factory, etc.

Dongxu Hydraulic Machinery Co.,Ltd&Jiangsu Helike Fluid Technology Co., Ltd.

MAIL: Jaemo@fsdxyy.com

WEB: www.dxhydraulics.com

WHATSAPP/SKYPE/TEL/WECHAT: +86 139-2992-3909

ADD: No.11, Seven Road, Lianhe Industrial Park,Foshan City, Guangdong Province ,China, 528226

& No. 7 Xingye Road, Zhuxi Industrial Concentration Zone, Zhoutie Town, Yixing City, Jiangsu Province, China

Post time: Dec-26-2022