Jiangsu HELIKE Fluid Technology Co., Ltd. is a wholly-owned subsidiary of Dongxu Hydraulics. It is specialized in the research and development, design, production and sales of aluminum plate-fin heat exchangers.

Focus on engineering/industrial machinery high-quality air-cooled oil radiators

foreword

Hydraulic and lubrication systems play an important role in almost all stationary and mobile machines. The fluid in the system transmits power, provides lubrication, transports heat, and prevents corrosion. The quality of the fluid is the fingerprint of the entire system. For example, the temperature control and purity of fluids are key factors in the overall control equipment condition in mobile hydraulic applications. In all hydraulic systems, energy is converted and transported. Such as disappearing in the form of heat. The task of the cooling system is to remove heat. An efficient cooling system can help extend the life of the working fluid and filters used and reduce life cycle costs.

Power Loss (Heat Power) Calculation Method

The selected model must be able to meet the requirements of system flow and heating power at the same time. Generally, it is selected by the following calculation method.

In the formula:

Pv=Power Loss [kw]

V = Oil Tank Capacity [l]

Coil = Equivalent Heat Capacity [kJ/kg K]

For Mineral Oil: 1.88kJ/kg K

ρ oil = Oil Density [kg/I]

For Mineral Oil: 0.915kg/I

△T=Temperature Rise of the System【℃】

t=Working Time【min】

P01 = Equivalent Cooling Power

T1=Expected Oil Temperature [°C]

T3=Ambient Temperature【℃】

η1 = Safety Factor of Heat Transfer Power

Generally, take 1.1

1. Power loss calculation method

Calculate the power loss of the existing equipment, and calculate the power loss according to the temperature rise of the oil by measuring the temperature rise of the oil within a certain period of time. It is usually obtained as follows:

Pv=△T*C oil*P oil V/T/60 (kW)

Example: Measure the oil temperature of a hydraulic system rising from 20°C to 45°C within 20 minutes, the capacity of the oil tank is 600L, and the system flow rate is: 200 L/min.

The thermal power produced is:

Pv=25*1.88*0.915*600/20/60≈21.5 (kW)

Then calculate the equivalent cooling power according to the best-expected oil temperature for the normal operation of the system:

P01=Pv/(T1-T3)*η1(kW/℃)

Assuming that the optimum expected oil temperature for the system is 55°C, the ambient temperature at that time is 35°C.

P01=21.5/(55-35)*1.1≈1.2 (kW/℃)

It is recommended to consider a 10% safety margin P01*1.1

P01=1.2*1.1=1.32 (Kw/℃)

That is: there is a power loss of 1.32kW/℃ to be dissipated through the air cooler.

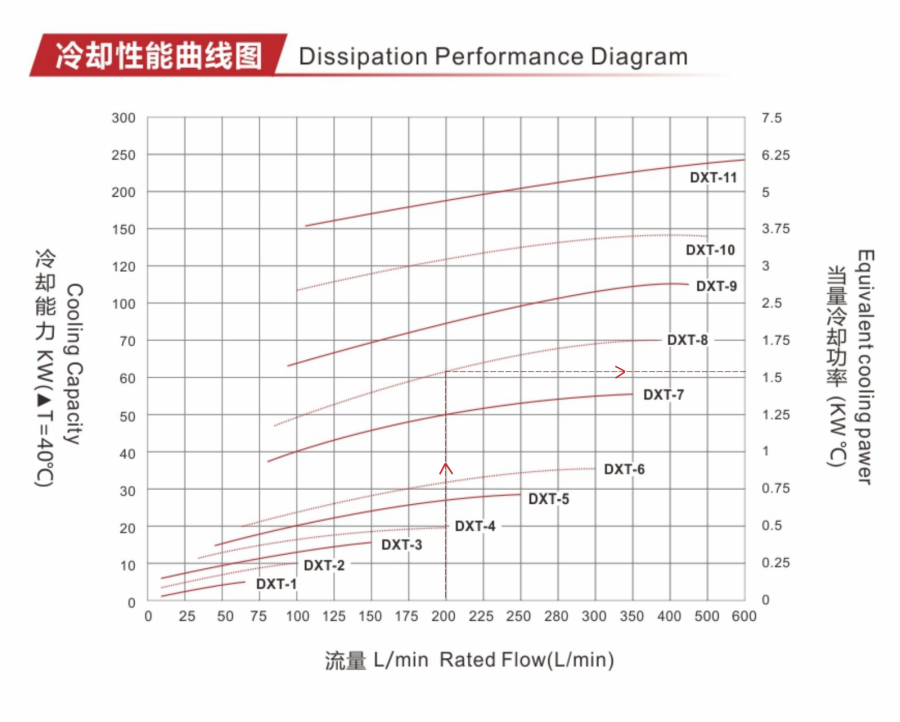

AIR COOLER SELECTION METHOD

When the flow rate is 200L/min, the equivalent cooling power is: 1.32kW/℃.

According to the graph, when the flow rate is 200L/min, the equivalent cooling power is equal to 1.32kW/℃ or greater than 1.32kW/℃. The selected model is DXT-8.

When the actual DXT-8 type cooler has a flow rate of 200L/min, the equivalent cooling power is 1.55kW/℃.

1.55kW/℃>1.32kW/℃

Foshan Nanhai Dongxu Hydraulic Machinery Co., Ltd. has three subsidiaries: Jiangsu Helike Fluid Technology Co., Ltd., Guangdong Kaidun Fluid Transmission Co., Ltd., and Guangdong Bokade Radiator Material Co., Ltd.

The holding company of Foshan Nanhai Dongxu Hydraulic Machinery Co., Ltd.: Ningbo Fenghua No. 3 Hydraulic Parts Factory, etc.

Foshan Nanhai Dongxu Hydraulic Machinery Co., Ltd.

&Jiangsu Helike Fluid Technology Co., Ltd.

MAIL: Jaemo@fsdxyy.com

WEB: www.dxhydraulics.com

WHATSAPP/SKYPE/TEL/WECHAT: +86 139-2992-3909

ADD: Factory Building 5, Area C3, Xingguangyuan Industry Base, Yanjiang South Road, Luocun Street, Nanhai District, Foshan City, Guangdong Province, China 528226

& No. 7 Xingye Road, Zhuxi Industrial Concentration Zone, Zhoutie Town, Yixing City, Jiangsu Province, China

Post time: Mar-06-2023