Plate condenser is a key equipment for rational utilization and conservation of existing energy and development of new energy. In the chemical production process, most of the heat transfer process is realized in the heat exchanger. In the modern chemical process, the investment in heat exchangers accounts for 30%-40%, so the form structure, parameter design, Performance improvement is of great significance to energy conservation, emission reduction and economic optimization of chemical processes.

During the heat transfer process, the latent heat with phase change is much greater than the sensible heat without phase change, so the steam condensation heat release is much higher than the single-phase heat transfer load. Plate heat exchangers have the characteristics of compact structure, high heat transfer coefficient, and can achieve high heat transfer load at a temperature difference of 2-3°C. In recent years, they have become the “new favorite” of the chemical industry.

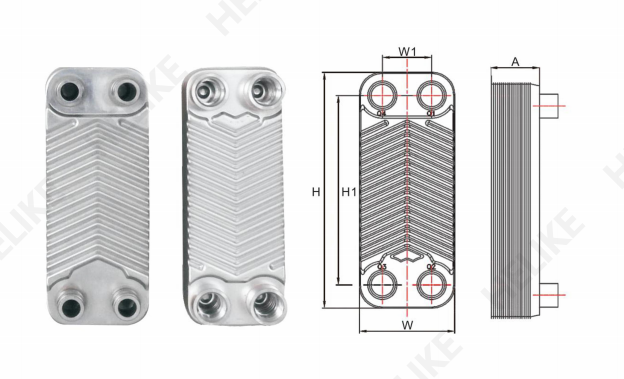

The plate condenser is composed of heat transfer plates, sealing gaskets, etc., to form a channel for medium circulation. Two different media flow in opposite directions in adjacent channels to complete heat exchange. Specifically, it is composed of plates, rubber seals, fixed plates, movable plates, compression bolts, upper and lower guide rods, etc.

Plate condensers have obvious advantages over traditional condensers:

1. Large heat transfer coefficient

Since the fluid flow between the plates is very turbulent and the plates are thin, the heat transfer coefficient is large. The heat transfer coefficient of a general plate condenser to water can reach 1500-4700W (㎡·K).

2. Compact structure

The unit volume equipment provides a large heat transfer area, with a heat transfer area of more than 250㎡ per cubic meter.

3. Great operational flexibility

Multi-stage operations or several operations can be carried out. Just install the intermediate partition at the appropriate position, so that one equipment can be used as several units. It can also adjust the number of plates to increase or decrease the heat transfer area or adjust the length of the flow channel to adapt to the requirements of hot and cold fluid flow and temperature changes. The operation is simple and convenient.

In addition, the plate condenser has the advantages of low metal material consumption and easy plate processing. The thickness of the plate is only 0.4mm-0.8mm. It has internal turbulence, which makes it difficult to scale. It is easy to clean by loosening the deposit bolt. In daily use, operation and maintenance are simple and convenient.

Post time: Dec-08-2023