Jiangsu HELIKE Fluid Technology Co., Ltd. is a wholly-owned subsidiary of Dongxu Hydraulics. It is specialized in the research and development, design, production and sales of aluminum plate-fin heat exchangers.

Plate-fin Heat Exchanger

Plate-fin Heat Exchanger

Material: aluminum alloy

Allowable maximum working pressure: 20bar (AJ0510 type: 8bar, AJ1025 type: 12bar, HLK31-70 type: 45bar)

Test pressure: 1.5 times the maximum working pressure

Maximum operating temperature: 130°C

Applicable fluids: those that do not react chemically with aluminum alloys, those that use a mixture of water and ethylene glycol

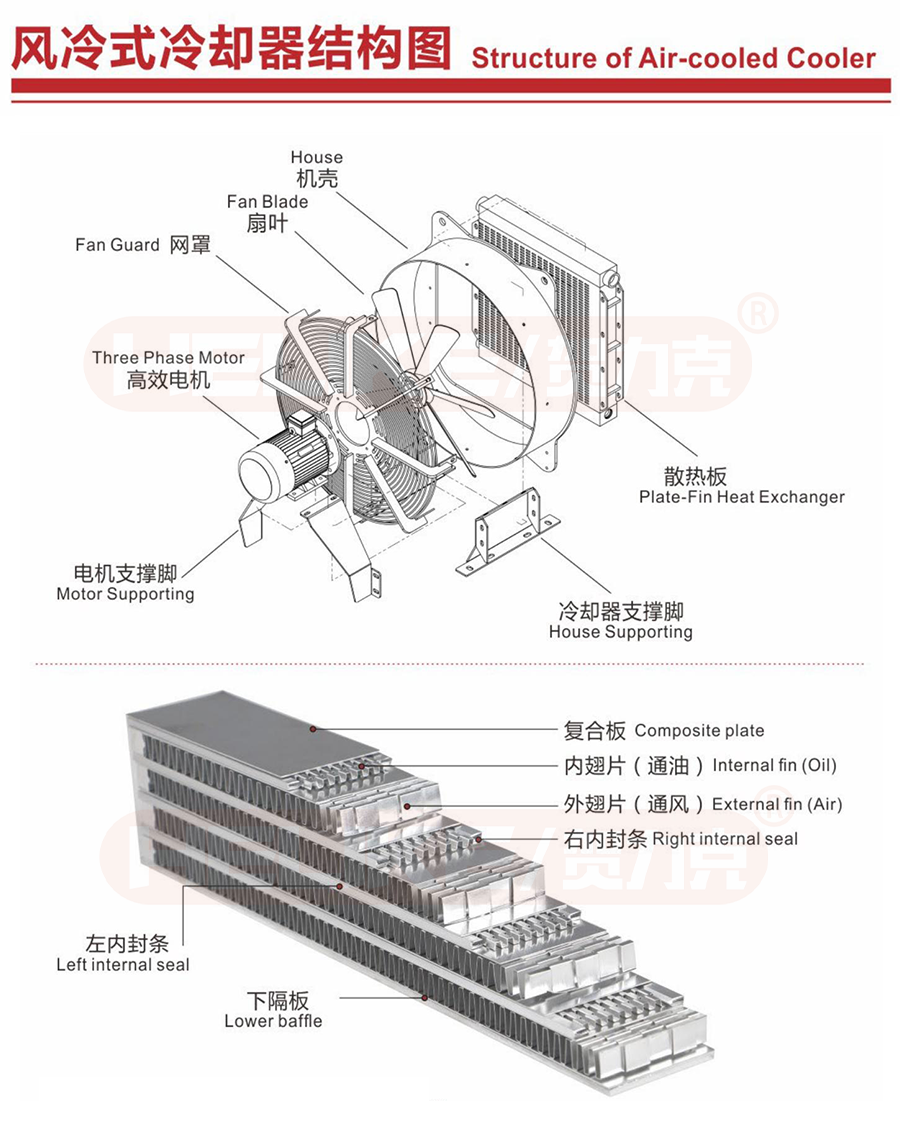

l The plate-fin cooler is characterized by its compact structure, light weight and better heat transfer efficiency.

l The oil flow channel is welded with inner fins, and the inner and outer fins ensure reliable welding and rapid heat conduction. It is not comparable to the copper tube socket method.

l Plate-fin coolers offer the best exchange capacity per unit compared to traditional copper tube or other heat exchanger types. At least 10-20 times the efficiency of the traditional copper tube type.

Structure and Characteristics

The plate fin is the basic element (heat transfer process: fin heat conduction and direct convective heat transfer between fin and fluid)

Basic hot spots: thin (good heat transfer), high (secondary surface area), small pitch (compact, pressure-bearing, easy

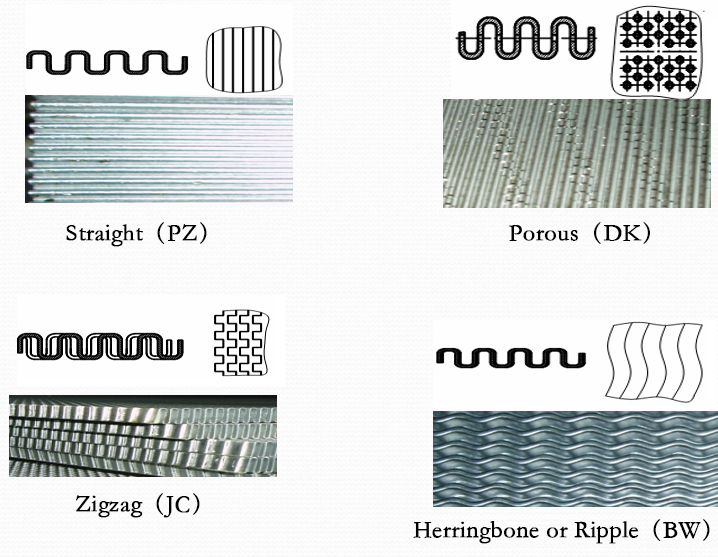

Heat Transfer Fins

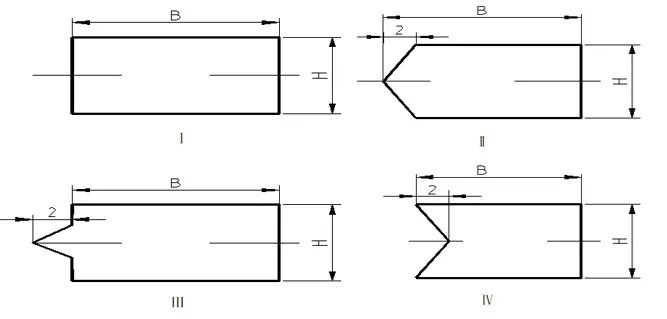

Features of Various Types of Fins

| Tooth Type | Features | Applicable Scope | Pressure Loss | Heat Transfer Efficiency |

| Straight(PZ) | Straight | General use | Low | Lowest |

| Porous(DK) | straight with holes | Various uses, especially with phase change, deflector | Low | Low |

| Zigzag(JC) | Straight tooth spacing 3~4mm | Commonly used, especially for low-pressure passages of air separation plants | High | High |

| Herringbone or Ripple(BW) | Smooth tooth spacing 10mm or longer serrated teeth | Viscous oils (disturbance), dusty gases (self-cleaning) | High | High |

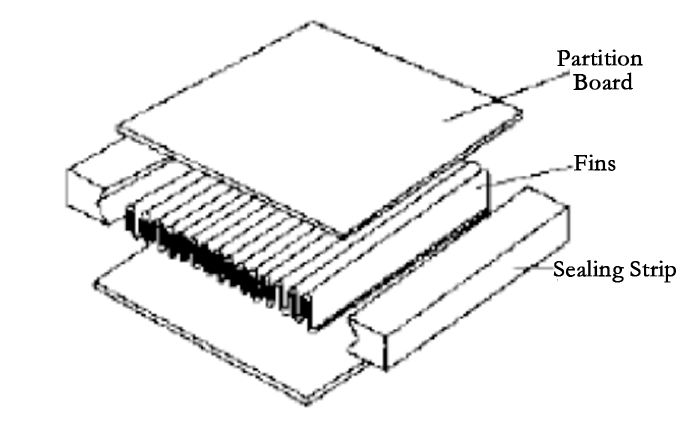

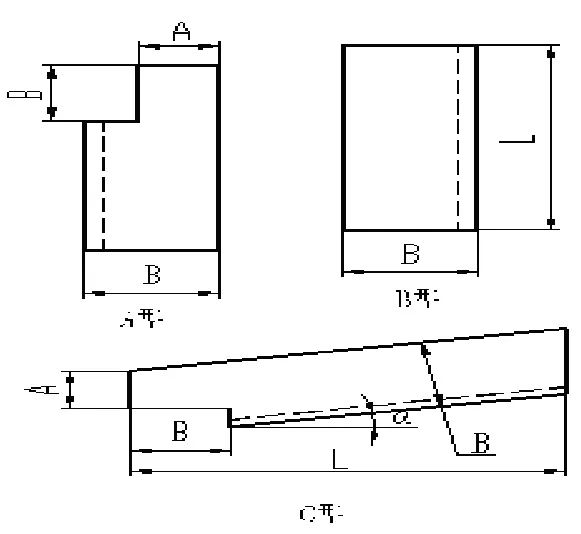

Sealing Strip

Sealing strips are around each layer to separate the medium from the outside world.

Sectional types of commonly used sealing strips.

Type of interface at the end of the sealing strip (longitudinal).

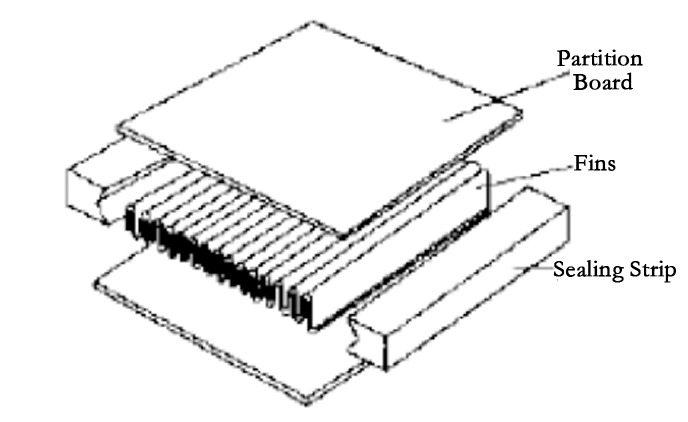

Partition Board

1. Composition: Metal Composite Panel

2. Function:

(1) Separate fluid

(2) Composite brazing filler metal

It is covered with a layer of brazing alloy (Al-Si-Mg) on the surface of the parent metal, and the alloy melts during brazing to weld the fins, seals and metal plates into one.

3. Commonly used partitions are generally 1mm~2mm thick.

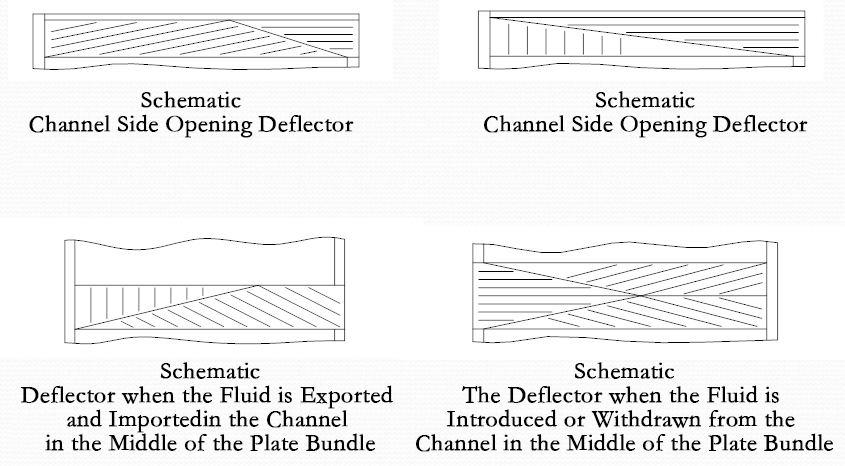

Deflector

1. Function: fluid import and export guide.

2. Formed by cutting with fins.

3. Generally use large pitch (flow diversion) such as 4.2mm.

4. Generally use a larger thickness (pressure bearing) such as 0.55mm.

5. Porous type for general use (flow diversion).

Special Cases

According to the width of the plate bundle and the opening position and opening direction of the deflector in the plate bundle, there are generally various types of deflectors as shown in the figure below.

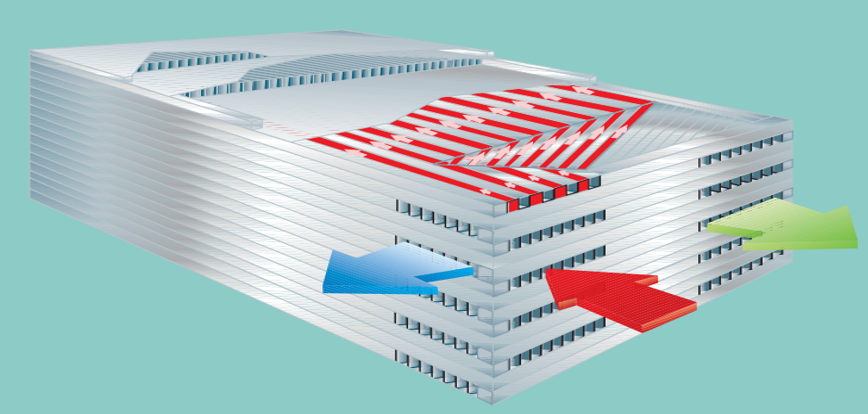

Plate Bundle Body

The plate bundle body is the place for heat exchange and is the main part of the heat exchanger.

The structural unit is the layer (channel). Each layer is composed of deflectors, fins, seals and partitions. According to the requirements of heat transfer, the plates are stacked together in order to form a plate bundle. The whole plate bundle body is vacuum brazed and cannot be disassembled. The layer structure is shown in the figure below.

Features

1. Multiple streams.

2. It can be drawn out in the middle (different temperature).

3. Runner inlet and outlet can be arranged on all sides.

Foshan Nanhai Dongxu Hydraulic Machinery Co., Ltd. has three subsidiaries: Jiangsu Helike Fluid Technology Co., Ltd., Guangdong Kaidun Fluid Transmission Co., Ltd., and Guangdong Bokade Radiator Material Co., Ltd.

The holding company of Foshan Nanhai Dongxu Hydraulic Machinery Co., Ltd.: Ningbo Fenghua No. 3 Hydraulic Parts Factory, etc.

Dongxu Hydraulic Machinery Co.,Ltd&Jiangsu Helike Fluid Technology Co., Ltd.

MAIL: Jaemo@fsdxyy.com

WEB: www.dxhydraulics.com

WHATSAPP/SKYPE/TEL/WECHAT: +86 139-2992-3909

ADD: No.11, Seven Road, Lianhe Industrial Park,Foshan City, Guangdong Province ,China, 528226& No. 7 Xingye Road, Zhuxi Industrial Concentration Zone, Zhoutie Town, Yixing City, Jiangsu Province, China

Post time: Jan-02-2023